At AGI glaspac, our approach to manufacturing is one of innovation and collaboration, working side by side with our customers to create a product that fits their needs perfectly and exceeds their expectations in beauty, function and quality. Glass offers great diversity in terms of visual and tactile enhancements, as well as the addition of secondary packaging, to differentiate premium products from competitors and increase shelf-appeal. Our wide range of "home grown” innovations and product enhancement services are testimony to the innovative approach we embrace at AGI glaspac, as well as the functionality and versatility of our glass offering. We are also committed to responding to the needs of niche markets and smaller clients, such as the microbreweries industry, for whom we regularly create turn-key glass packaging solutions.

Hyderabad

Our offering has been extended to include a comprehensive bottle design service, a glass analytical laboratory and a glass training school. Our technical team is also available 24 hours a day, seven days a week, for glass filling line support, providing critical spares, glass equipment repair and overhauls.

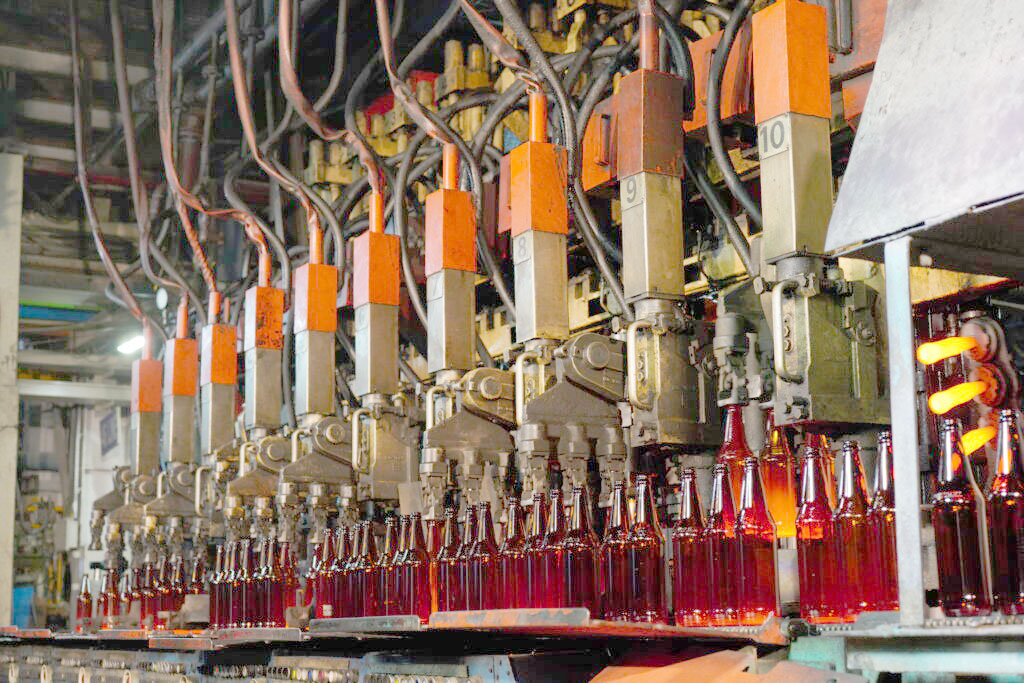

The technology for production of glass containers by NNPB method (Narrow Neck Press and Blow ― press-and-blow developing of lightweight narrow-necked glass container products) was implemented and mastered.

The plant has implemented management system of safety and quality of products in accordance with the International Standard BRC (integrated system, which includes the requirements of ISO 9000 standards, FSSC 22000).

Total Capacity of this Plant is 600 Tonnes/Day

Bhongir

AGI glaspac is committed to technical expertise and manufacturing competence – to generate sustainable value and deliver on all customer expectations. That includes maintaining the highest possible levels of compliance and adherence to international manufacturing standards.

We constantly review and benchmark production efficiencies and productivity outputs against international standards, this coupled with a commitment to human capital and skills development ensures that we are equipped to address present and future demands.

The company uses only natural raw materials in production and manufactures environmentally friendly products, featuring a high degree of water and chemical resistance, considerable strength, reference colors, and perfect geometry. This plant has 11.5 MW of Installed Solar Capacity.

Total Capacity of this Plant is 1000 Tonnes/Day

The implemented system of glass coloration in the feeder allows within a matter of hours to transfer from colorless glass to any color range at the customer’s option. Presently, the company employs approximately 3000 people. Highly skilled managers supervise production.

The enterprise development strategy is aimed at increasing the production volume of glass containers while maintaining and improving the quality of the products.

Our results speak for themselves:

- Offers a variety of high-quality glass packaging solutions at competitive prices

- Guarantees supply, thanks to superior supply chain management and optimisation

- Enhances customer bottom line through value enhancement and cost reduction/optimisation initiatives

- Has a broad and established customer base, underpinned by long-standing customer relationships

- Provides a full capability mould manufacturing facility, reducing cost and shortening new product development lead time

Batch House – “ZIPPE”, Germany

Batch House Mixer – “Teka”, Germany

Furnace – “SORG”, Germany

I/S Machine – “Emhart”, Sweden

Hot End Handling – “SHEPPEE”, UK

Annealing Lehrs – “PENNEKAMP”, Germany & “Antonini”, Italy

Inspection Machines – “Emhart”, USA

Mould – “Sonicam”, France & “Hass Lathe”, USA

Q.C. & Testing Equipment’s -“AGR”, USA

ACL – “Strutz”, USA

Automated Packaging – “Clearpack”, Singapore